About GF FGS

FGS became part of GF Piping Systems, and is now called GF FGS. Together with GF Piping Systems, we specialize in the safe and reliable transport of water, chemicals and gases. Our focus is on plastic piping systems, complete solutions and services. The product portfolio of fittings, valves, pipes, automation and joining technologies covers all water cycle applications.

GF Piping Systems is present with its commercial subsidiaries in 34 countries and we have more than 30 production plants in different countries of the world.

GF FGS

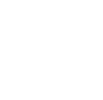

The largest manufacturer of polyethylene systems for transporting fluids and gas.

34 Different Countries

We have more than 30 production plants in different countries of the world.

50 Years Warranty

We offer a full 50-year warranty on our entire GF FGS product line.

Special Support

We are available to offer the best support and service you deserve.

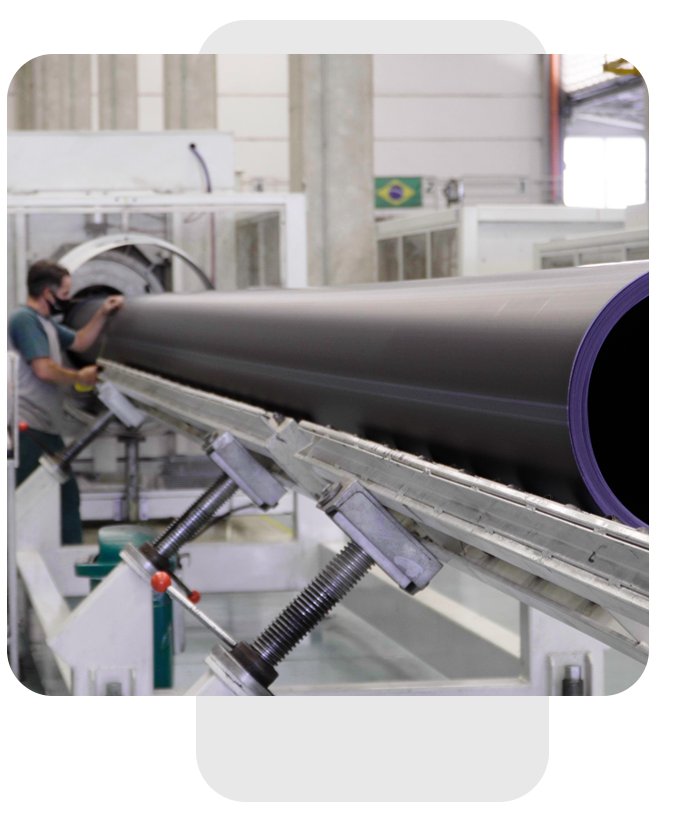

HIGH DENSITY POLYETHYLENE (HDPE) PIPING SYSTEM

HDPE pipes have greater resistance to corrosion, impacts (does not break) and greater flexibility. Its installation is quick and practical, which speeds up the progress of your project. The final cost of the work is lower due to the low number of splices that the system provides throughout the assembly.

The HDPE piping system manufactured by GF FGS are made in PE80 and PE100, from 20 mm up to 1.600 mm external diameters, from PN4 up to PN25.

Can be supplied in 50m, 100m or 200m coils or from 6m up to 18m in bars and according to the Brazilian Standard are made with colored resin (yellow, orange, blue or black) with or without identification stripe.

Get Ready to Be Surprised

HDPE Pipes Advantages

-

Diameters and pressure class variety

-

Higher chemical resistance and abrasive resistance

-

Higher impact resistance

-

Corrosion free

-

Higher hydraulic characteristics

-

Non-toxic material

-

Low roughness

-

Higher lifetime low weight and high flexibility

-

Easier handling, storage and installing

-

Higher incrustation resistance

-

Squeeze off capacity

Applications

-

Gas and Biogas pipelines distribution network

-

Water Distribution, branches and main pipelines

-

Sanitation, under water, inland main pipelines outfalls

-

Optical fiber, telephones and electrical pipelines

-

Irrigation and drain water pipelines

-

Chemical fluids, effluents and waste water pipelines

-

Dragging and solid parts transportation pipelines for mining

-

Fire protection pipelines for industrial and refineries

-

Plastic piping systems for indoor wat/er distribution network

-

Plastic piping systems for cooling for industrial network

-

Oil and fuels fluids pipelines